Product description

CV600 grout is made based on expanding materials and with Adding only water to it achieves the desired properties.• This product is ready to use and does not need any additives It has nothing but water. • Any contamination, grease, paint, bitumen, excess cement mortar and Remove dust from the surface. • The place of application should be washed 24 hours before application.

This product is based on cement and does not shrink after it loses its water.

For example, when the pressure needs to be transferred from the base of the shed to the foundation, they use grout.

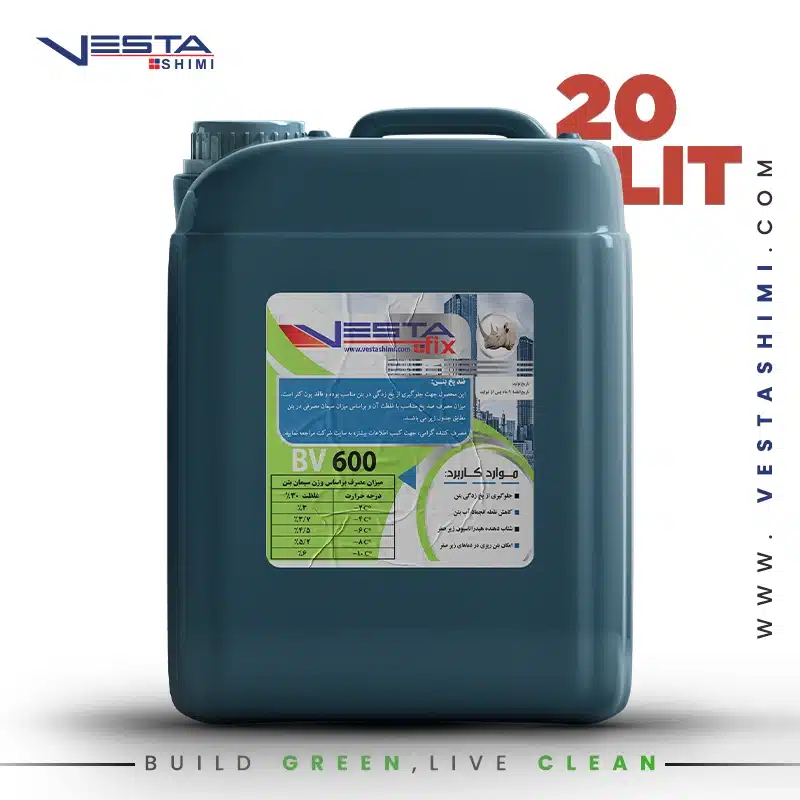

In Vestashimi Spadana company, in order to increase the mechanical resistance of the grout, this product is prepared using polymer materials to strengthen the properties of the grout. This product is prepared based on expanding materials and by adding water to it, it obtains the properties mentioned in the table below.

This grout is ready to use and does not need any other additives except water.

Advantages

- High compressive strength

- Resistant to atmospheric factors

- Without chloride and metal compounds

- Smooth and non-shrinking mortar for use with restrained expansion properties

Indications

- For use under pages of columns

- For the foundation of machines

- Bolt installation and concreting of concrete boxes

- Injection under the foundation, concrete shoring and repair of columns and bridges

- For use in all kinds of concrete compounds that require expansion

- Making expandable cement grouts without shrinkage

How to use

To use this product, we first pour 4 liters of clean water into a container with a capacity of 25 kilos of mortar, then we start adding grout powder to the water and start mixing at the same time.

until the result becomes a smooth paste. After the dough is ready, we give it 10 minutes for the ingredients in the prepared dough to become consistent, then we start mixing again and the resulting mortar is ready to use.

We close the area around the desired area using a mold and pour the mortar to the desired level in the mold.

Due to the fact that CV600 grout has long-lasting resins, it should be waited until it dries.

This mortar hardens more slowly than cement mortar. The final resistance time is approximately 28 days.

tip

Before use, the work surface must be cleaned and free of any dust particles.

Packaging and storage conditions

Expiration Date: 9 months after production.

Storage: Keep in +10 to +40 C, away from heat, humidity and direct sunshine.

Groot

These products are based on water, cement and sand. Grouts have different characteristics, which has caused them to have different uses. Before buying grout, you should pay attention to its application and uses, because cement-based grout and epoxy grouts are two- and three-component, and the efficiency of each is different from the other.

Types of grouts

These products are of various types, including: Expansive cement-based grouts, modified cement grouts, two-component or three-component epoxy grouts are ready-expandable grouts. Keep in mind that each of these products have different functions and are used depending on the required conditions. These products are classified as dry powder, and when combined with water, they have special characteristics of two-stage volume expansion.

Polymer groups: Cement grouts modified with polymer materials have two components that are enough to mix these two components together during grouting. Characteristics of polymer grouts include: High tensile and bending strength, good sealing properties, high abrasion resistance, strong bond with mineral infrastructure, high resistance to the effect of sea salt water.

Epoxy grouts: Formable and solvent-free epoxy grout consists of 3 components, which need to be mixed together when using. Properties of epoxy grouts include: One of the characteristics of epoxy grout is its high strength and adhesion, which, in addition to high mechanical and chemical resistance, is an ideal material for all types of repair work and installation of super heavy machinery that requires high adhesion and very high compressive and bending resistances. The main characteristics of these types of grouts: Fast hardening of the structure, which depends on the ambient temperature, resistance to strong vibrations, high adhesion to mineral and steel works, hardening without shrinking and resistance to chemical attacks, high mechanical resistance.

Grouting methods

In general, there are two methods of grouting inside the holes, which include the following. Grout or dry mortar: In this method, the mortar is placed using compression force. Fluid Grout: Due to the flow during pouring, the grout is placed automatically. The liquid grout method is widely used in places where the holes are almost closed and inaccessible and outside of which grouting is not easily possible.

General method of use and implementation:

The intended surface for grouting must be free of any oil, dust and dirt pollution. For 2 to 3 hours before grouting, the surfaces should be completely submerged and during grouting, the excess water should be dried from the surface. The column plates under which the grout is to be inserted must be completely cleaned of contamination and holes must be installed on them for the air to escape. The space that is going to be filled with grout must be shaped in such a way that no moisture leaks from it. Prepare the grout mixture according to the instructions on the package.

There are no reviews yet.